Flexible Rod Buckling Under Torque

3 min read • 445 wordsGeometrically nonlinear analysis of a shaft buckling under torsion.

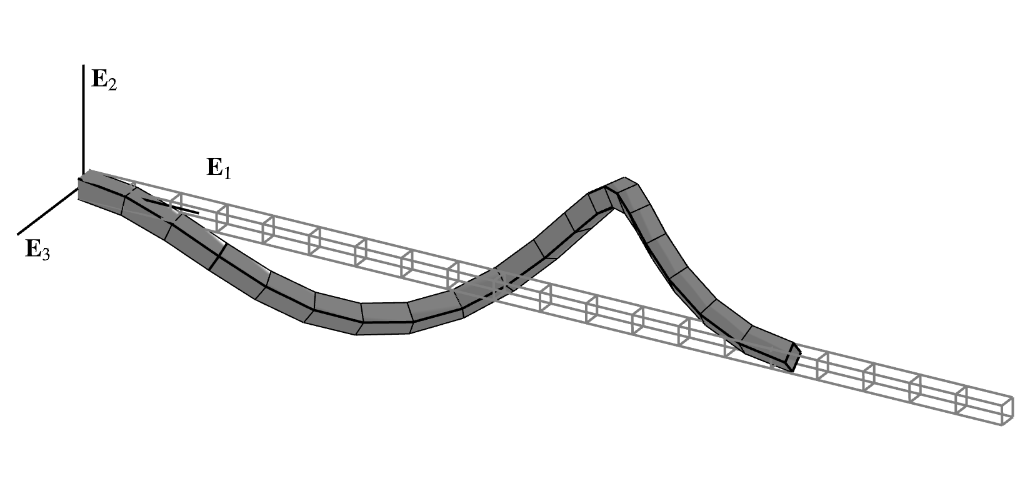

The hockling shaft (rendered above using the

veux

library)

is a particularly complex problem that arises from practical considerations for the design of propeller shafts in

large ships .

This post follows from the work by .

The problem is posed as a propped cantilever with a torque

applied at its end

.

In OpenSees, this is defined as follows:

The rod is fixed at the origin and is free to translate along the direction at its end.

This problem was investigated analytically by who found an approximate minimum buckling torque given by:

reports the value , which is commonly used in the literature. Because the loaded end is constrained to rotate about a fixed axis, all rotation parameterizations coincide at this node so that, in all cases, the moment can be applied by simple scaling of a reference vector.

The following parameters are commonly adopted for the problem

To induce bifurcation, the undeformed centerline is slightly rotated off the axis of the roller reaction:

The simulation uses a discretization of

20 elements for the rod, and the torque is applied in 65 increments with

iterative and incremental load factor control. The analysis uses the

SFIN isometry with both None and Incr interpolation and

parameterization variants.

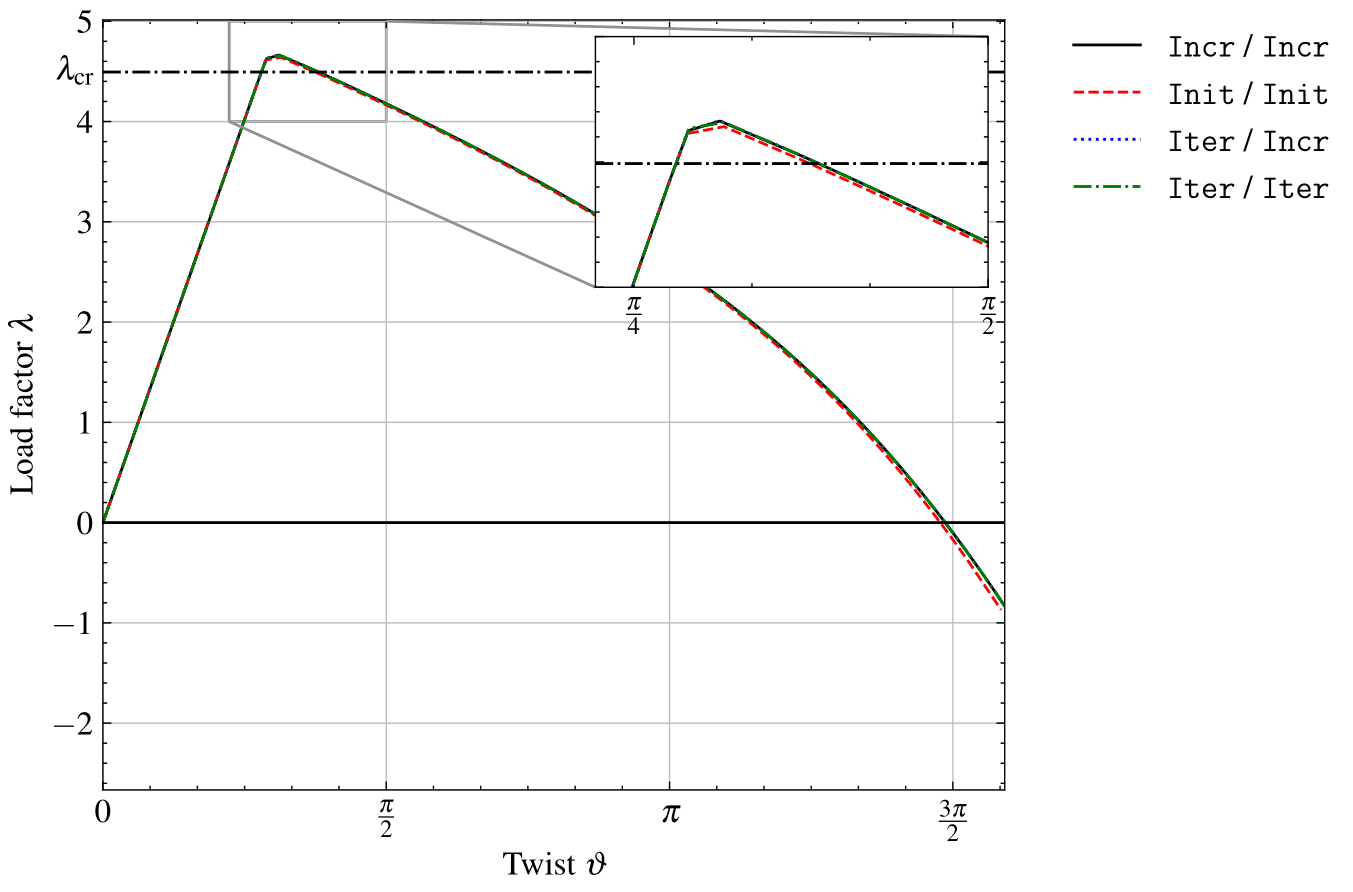

Figure 2 shows the relation between load factor

and end rotation

. This figure

shows that the buckling load of the simulation is slightly higher than

the value derived by , but is consistent with

findings for geometrically exact elements in the literature

.

This investigation leveraged the FEDEASLab toolbox for nonlinear finite element analysis.

Documentation is under development and expected to be published in Summer 2025.

Source code for the geometric transformation framework is available on

GitHub

.